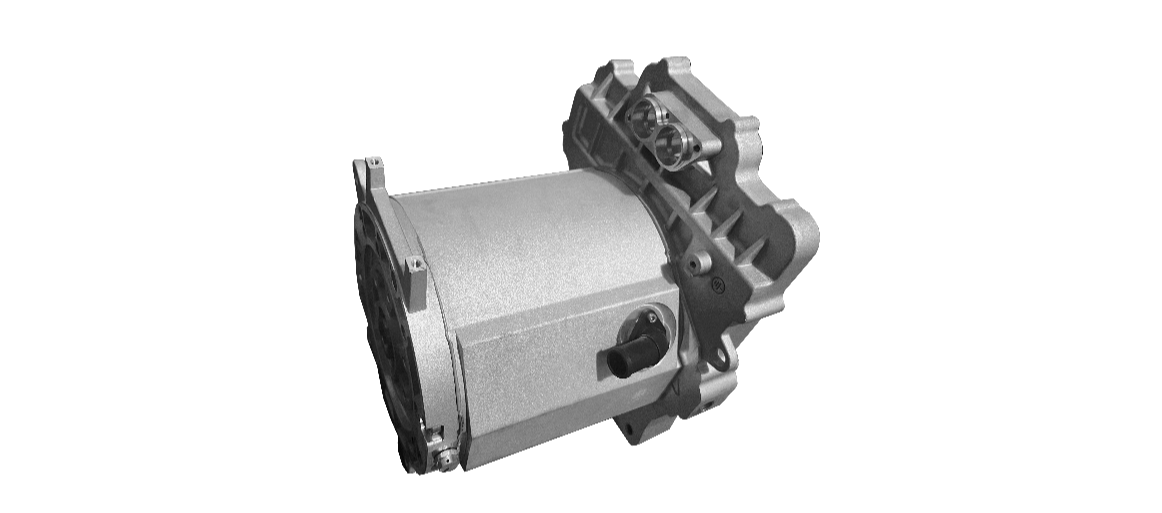

Product characteristics

-

Platform basedWolong has an OD146-OD530 motor punching platform. A motor punch has multiple power segments, and the platformization of motors facilitates customer installation and effectively reduces costs.

-

Product consistencyWolong has multiple intelligent motor production lines. Equipped with fully automated winding and embedding machine and robot automation integrated system, it can achieve fully automated production and ensure stable product quality

-

EfficientThe motor adopts high-performance permanent magnets. It has the characteristics of high power density, high efficiency and energy saving. The max efficiency of the motor is ≥ 97%, and the proportion of the high-efficiency zone is ≥ 90%.

-

High reliabilityThe laboratory has obtained CNAS (China National Accreditation Service) certification.Covering over 85 testing items such as input-output characteristics, safety, environmental adaptability, reliability, NVH, etc

Motor specification

| Rated voltage (VDC) | 336 |

| Rated power (kW) | 30 |

| Rated torque (Nm) | 70 |

| Rated speed (rpm) | 4093 |

| Insulation level | H |

| Weight (kg) | 30 |

| Cooling method | Liquid cooling |

| CEMF (Vpeak) | 630@12000rpm |

| Peak power (kW) | 70 |

| Peak torque (Nm) | 176@60S |

| Max speed (rpm) | 12000 |

| Protection level | IP67 |

| Peak current (Arms) | 230 |