Recently, Wolong Electric Group successfully completed “5G intelligent transformation” of motor winding machine for EV workshop with the help of China Mobile. This project is the FIRST 5G transformation project for data collection of industrial automation production equipment in electromechanical manufacturing industry within Zhejiang Province.

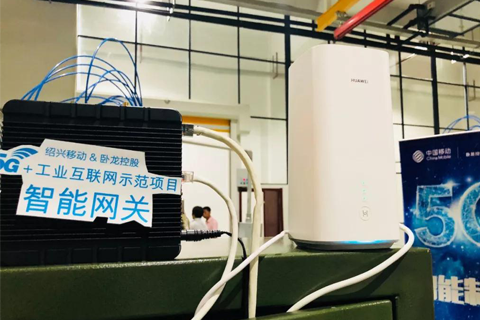

The traditional way of interconnecting production data by wire has the disadvantage that the maintenance cost increases greatly owing to the aging pipeline and the adjustment of equipment in later period. In this pilot project, China Mobile deployed 5G intelligent gateway and CPE in Wolong EV workshop, and industrial network, protocol converter and 5G CPE were safely networked. Wolong can upload the related data to cloud management platform by 5G network to realize the interconnection of the equipment and the cloud platform. As a result, the collected production data could be updated in real time along with the product processing of the automation production line equipment. Thanks to the characteristic of 5G ultra low latency, the data update speed will be greatly improved and the wiring cost will also be greatly reduced.

Ma Hailin, the director of Information Management Department of Wolong Electric Group, said that replacing wired deployment with 5G wireless deployment will be expected to save wiring costs and wiring time, and the project also provide reliable solutions for applications in subsequent wireless scenarios in Wolong. For example, the interference existing in the AP coverage scene inside the factory can be solved by 5G technology. In the future, Wolong will further explore the 5G applications in the Black Light Factory Intelligent Manufacturing Project, the IoT Platform Construction Project, and the 5G Retrofit Project for AGV Car.

English

English

中文

中文

Deutsch

Deutsch

日本語

日本語

English

English

한국어.

한국어.